Microtunnelling / Pipe Jacking

Microtunneling is a Trenchless construction method used to install pipelines beneath highways, railroads, runways, harbours, rivers, and environmentally sensitive areas. Microtunneling is defined as a remotely-controlled, guided pipe-jacking operation that provides continuous support to the excavation face by applying mechanical or fluid pressure to balance groundwater and earth pressures. Support at the excavation face is a key feature of microtunneling; distinguishing it from traditional open-shield pipe-jacking.

Microtunneling requires jacking and reception shafts at the opposite ends of each drive. The microtunneling process is a cyclic pipe jacking operation. A microtunnel boring machine (MTBM) is pushed into the earth by hydraulic jacks mounted and aligned in the jacking shaft. The jacks are then retracted and the slurry lines and control cables are disconnected. A product pipe or casing is lowered into the shaft and inserted between the jacking frame and the MTBM or previously jacked pipe. Slurry lines and power and control cable connections are made, and the pipe and MTBM are advanced another drive stroke. This process is repeated until the MTBM reaches the reception shaft. Upon drive completion, the MTBM and trailing equipment are retrieved and all equipment removed from the pipeline.

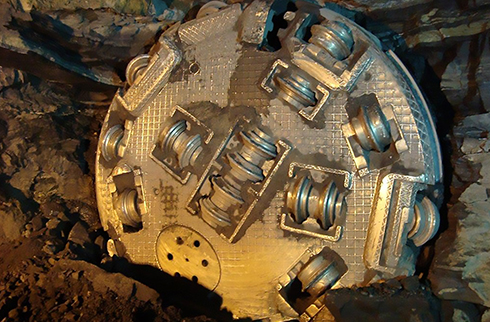

MTBMs have a rotating cutting head to excavate the ground material, a crushing cone to crush larger particles into smaller sizes for transport through the slurry lines, a hydraulic or electric motor to turn the cutting head, a pressurized slurry mixing chamber behind the cutter head to maintain face stability, an articulated steering unit with steering jacks for steering corrections, various control valves, pressure gauges, flow meters, and a data acquisition system. Additionally, the MTBM has in-line cameras to relay information to the operator and a target system for guidance control.